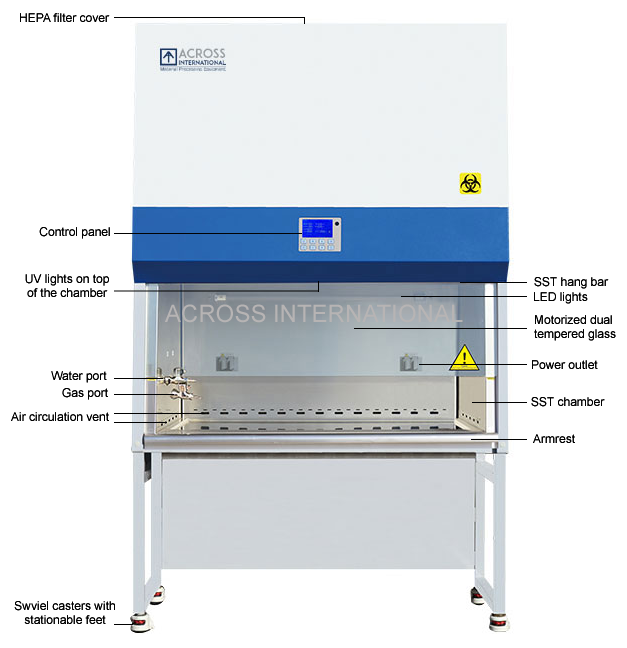

Specifications

| Model | BC-6F |

| Electrical requirements | 110V 60Hz 1-Phase 500 watts |

| Chamber | Dimensions: 67 x 23.5 x 26″ (WxDxH)

Material: 304 stainless steel

Power outlet with cover: four, < 500 watts

Water port x 1, stainless steel

Gas port x 1, stainless steel

Surface height from ground: 29.5″

Hanging bar: stainless steel, with 10 hooks |

| Lights | LED lights: 22W x 2, > 1000 Lux

UV lights: 30W (Germicidal UV lamp, emission 253.7 nanometers)

* UV lights available only when front glass panel is fully closed.

* Recommended replacement interval: 600 hours |

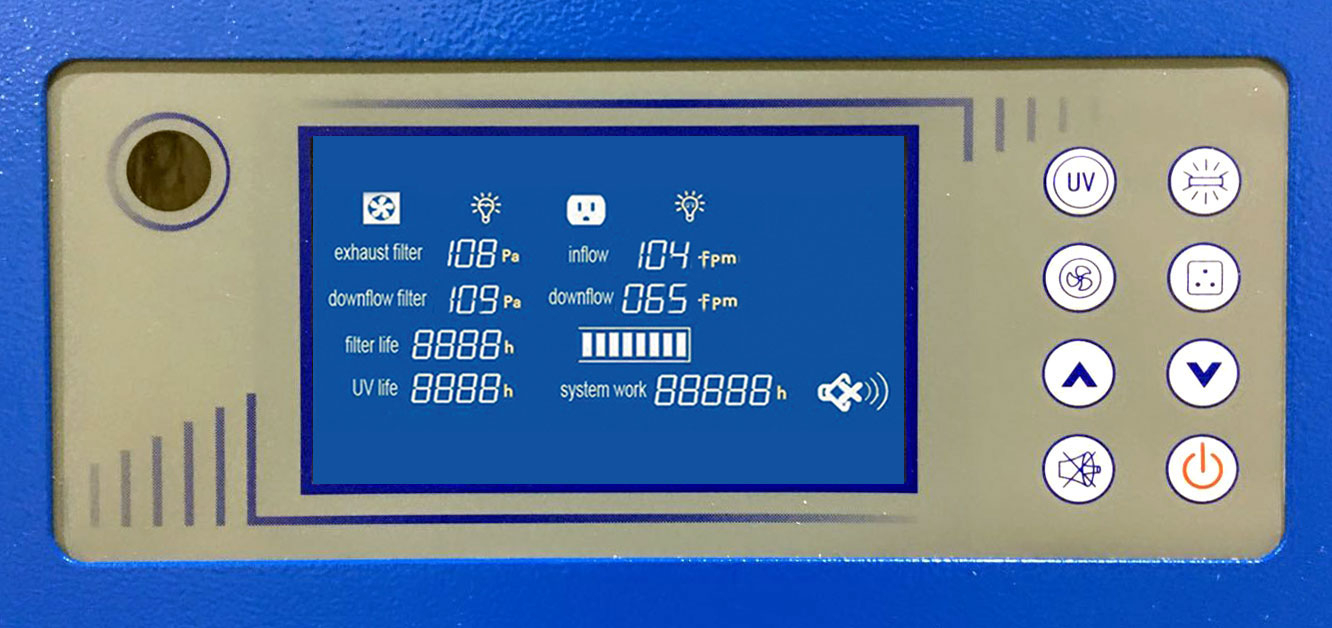

| Air flow | Volume

Inflow: 825 CFM (Cubic Feet per Minute)

Downflow: 710 CFM

Exhaust: 485 CFM

Speed

Inflow: 100-110 FPM (Feet per Minute)

Downflow: 60-70 FPM

* 70% recirculated internally, 30% discharged from top vent

* Air circulation available only when front glass panel is open |

| Top clearance | 12″ (recommended) |

HEPA (High-Efficiency

Particulate Air) filter | Two, with 99.999% efficiency at 0.3 μm diameter

Filter hour indicator and life bar on controller

* Recommended replacement interval: 4,000 hours |

| Front safety panel | Material: tempered safety glass (thickness > 5mm), dual-layer, laminated, UV blocking

Recommended opening height: 10″

Maximum opening height: 20.5″ |

| Material | Chamber: 304 stainless steel

Main body: powder coated steel |

| Controller | LCD screen with soft touch buttons and remote control |

| Noise | < 65 dB(A) |

| Casters | Four, with stationable feet |

| Unit/shipping dimensions | 73.5 x 30.5 x 90.5″ (fully assembled) / 79.5 x 42.5 x 75″ (WxDxH) |

| Shipping weight | 820 Lbs |

| Safety | Abnormal airflow alarm

Filter replacement alarm

Front glass panel unsafe height |

| Compliance | NSF/ANSI 49 (C0559576) |

| Warranty | One year |

Caution! Installation requires a forklift or a crane.

Attention! Steps before and after using the unit.

- Step 1: Fully close the front glass panel, turn on UV light for 30 mins (you can use the timer setting). Users should leave the room during this disinfection period.

- Step 2. Raise the glass panel to recommended opening height, turn on air circulation for 10 minutes.

- After operation is done, fully close the glass panel and turn on UV light for another 30 minutes for decontamination.

IMPORTANT GUIDELINES USING A BSC

- No flammable and explosive substances (Building up of flammable material may cause an internal fire or explosion)

- No volatile chemicals (May cause damage to HEPA filters to the point where it allows particles to leak through)

- No toxic chemicals or materials (May reach room occupants)

- No open flame (Will disrupts air flow patterns)

- Minimal use (10mL or less) of decontaminant, such as 70% isopropyl or ethyl alcohol is allowed.

- We recommend using the following for disinfecting the surfaces of a BSC, depending on the agent to be controlled: Sodium hypochlorite (bleach), Ilodophors (Wescodyne), Phenolics (Hilphene, Vespene) and Quaternary ammonium compounds (Conflikt, EndbacII)

- If gaseous, vaporized or aerosolized chemicals must be generated in a BSC, you should assure yourself that the quantity being generated will NOT cause a flammable or toxic risk.